| Parameter | Capability |

|---|---|

| Layer count | 1-40 layers |

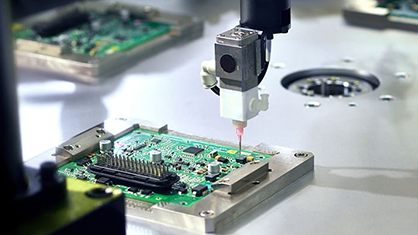

| Assembly Type | Through-Hole (THT), Surface Mount (SMT), Mixed (THT+SMT) |

| Minimum component Size | 01005 or 0201 (lmperial)/ 0402 or 0603 (Metric) |

| Maximum component Size | 2.0 in x2.0 in x0.4 in (50 mmx 50 mm x10 mm) |

| Component Package Types | BGA, QFN, QFP, SOIC, SOP, SSOP, TSSOP, PLCC, DIP, etc. |

| Minimum Pad Pitch | 0.5 mm (20 mil) for QFP, QFN, 0.8 mm (32 mil) for BGA |

| Minimum Trace width | 0.10 mm (4 mil) |

| Minimum Trace Spacing | 0.10 mm (4 mil) |

| Minimum Drill size | 0.15 mm (6 mil) |

| Maximum Board Size | 18 in x 24 in (457 mm x 610 mm) |

| Maximum Board Thickness | 0.062 in (1.6 mm) to 0.125 in (3.2 mm) |

| Board Material | FR-4, High-Tg FR-4, Aluminum, High Frequency, Flexible(FPc), Rigid- Flex, Rogers, etc. |

| Surface Finish | HASL, lmmersion Gold, Gold Finger, OsP, lmmersion Silver, etc. |

| Solder Paste Type | Leaded or Lead-Free |

| Assembly Process | Reflow soldering, Wave soldering, Hand soldering |

| Inspection Methods | Automated Optical inspection (AOl),X-ray, Wisual Inspection |

| Testing Methods | In-Circuit Test (lcT), Functional Test (FCT), Flying probe test |

| Design for Manufacturing (DFM) | DFM Analysis and Feedback |

| Turnaround Time | Prototype: 24 hours to 7 days, Production: 10 days to 4 weeks |

| PCB Assembly Standards | IS09001:2015:IS013485:2016:ROHS,UL 94V0, IPC-600G classll and IPC-6012B classll standard |